The laboratory

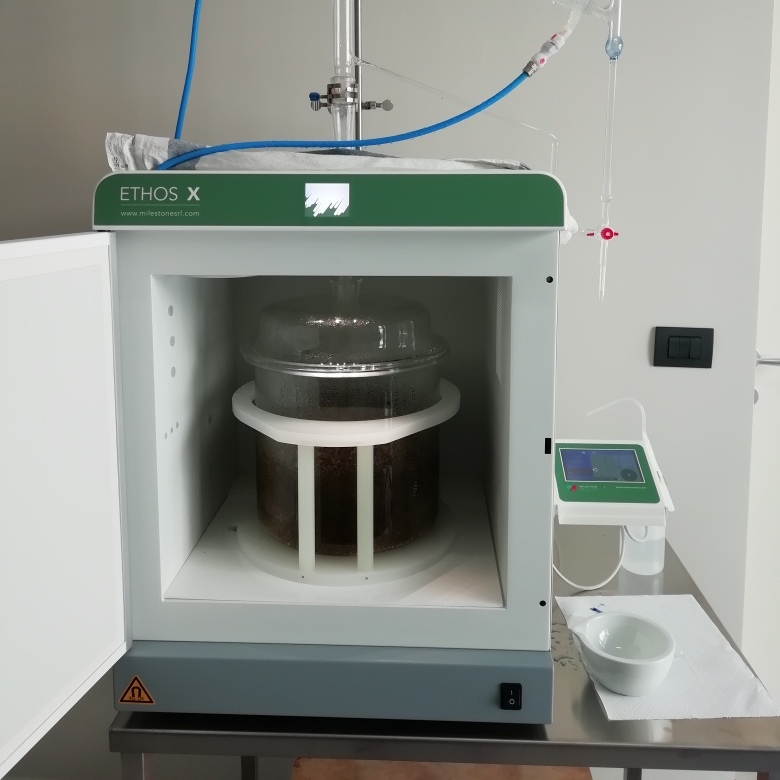

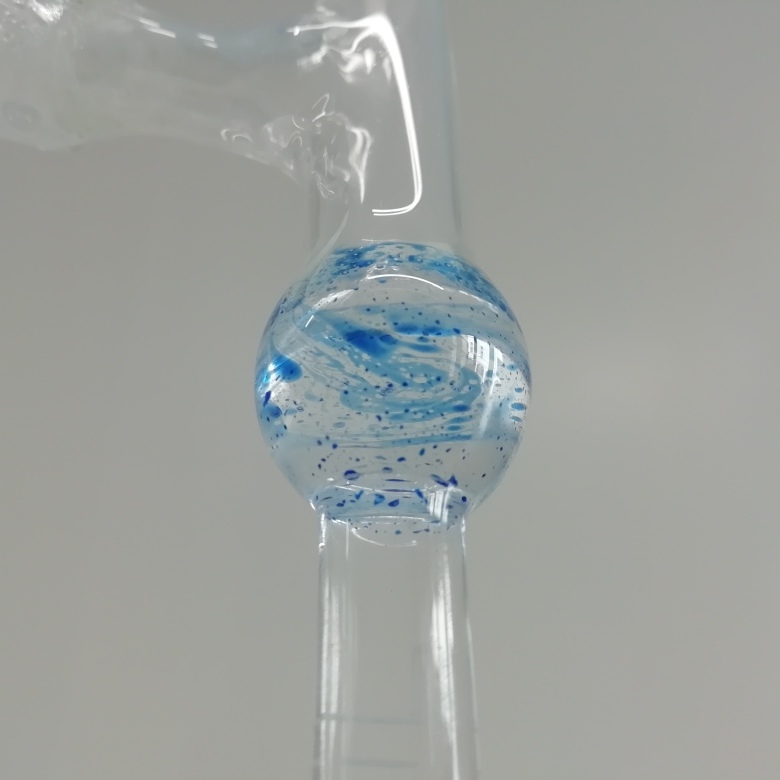

Equipped with state-of-the-art machinery, laboratory is a place of exchange, open to local producers and dedicated to high-profile experimentation in the field of aromatic herbs in some key areas.

Essica Lab is at Palazzo Taffini d’Acceglio, entrance in Via Antica Contrada delle Beccherie, Savigliano 12038 (CN)

(T: +39 0172 86472 – M: essicalab@leterredeisavoia.it)