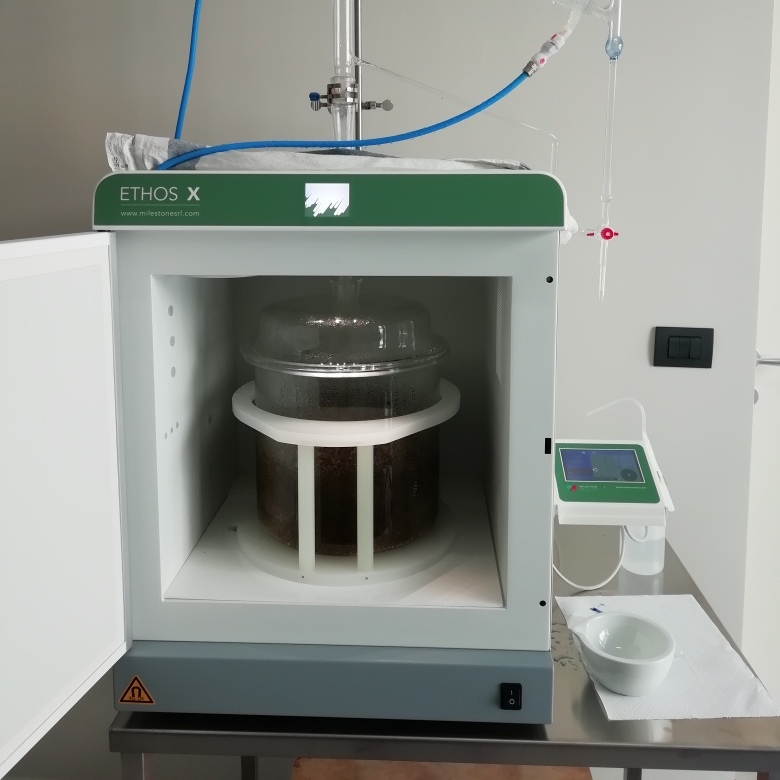

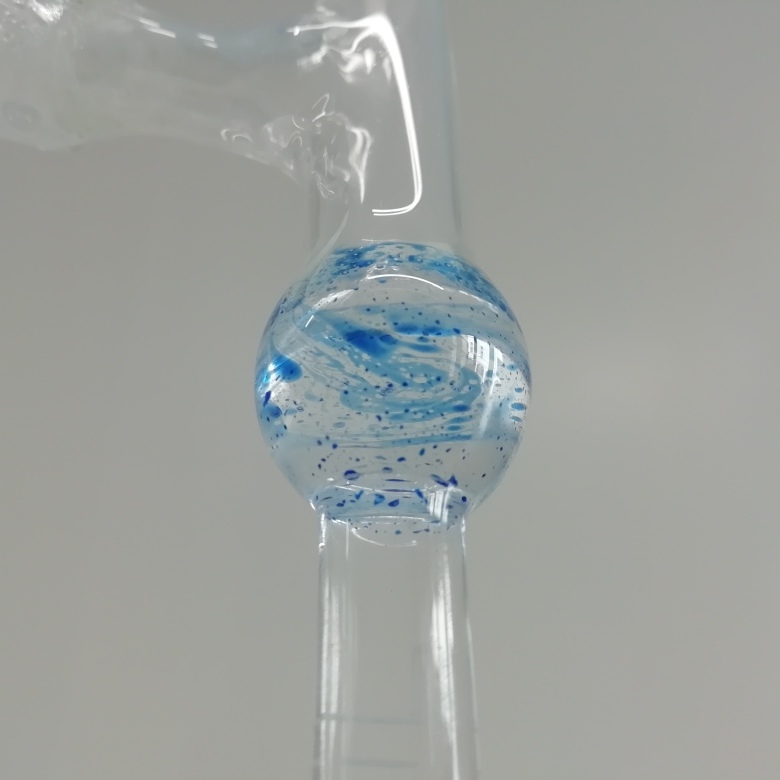

Ultrasounds are sound wave emissions (20 KHz to 60 KHz) produced by special switches that transform electrical energy into mechanical vibrations. These are transmitted inside the extraction chamber where the raw material is immersed in the chosen solvent and create micro-bubbles of air that implode and cause a shock wave, called cavitation. This results in the disruption of the plant matrix architecture and the disintegration of cellular structures with the consequent release of the active ingredients that solubilize in the solvent. This is an innovative, clean, quick and easy extraction technique that allows the production of high-quality phytoextracts.

The technology can be applied in various fields such as the food industry, liquor industry, herbal industry, cosmetic industry, classical pharmaceutical, homeopathic pharmaceutical, veterinary pharmaceutical, biochemistry and green chemistry, and agriculture.